Dr. PhD Marina D’Antimo | Steligence ArcelorMittal, Milano, Italy

Eng. PhD Marion Charlier | Steligence ArcelorMittal, Esch-sur-Alzette, Luxembourg

Prof. Dr. Olivier Vassart | Steligence ArcelorMittal, Esch-sur-Alzette, Luxembourg

Eng. Walter Swann | Steligence ArcelorMittal, Solihull, United Kingdom

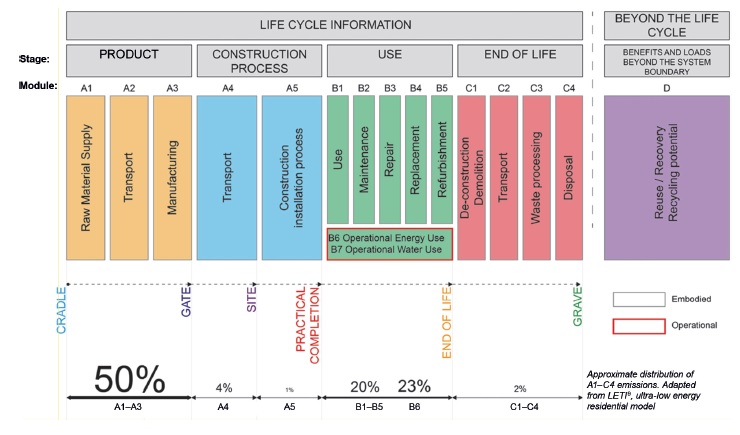

The constant increase in the global population is leading to a severe exploitation of our natural resources, a more rational use of these resources is becoming an unavoidable necessity. Almost everything we use daily is entirely or partially made of/with steel. The use of steel is expected to increase to meet the demographic upsurge and the evolving needs of society. Primary steel making is responsible for high emissions and designers must strive to reduce the embodied carbon of the built environment to stem the climate crisis. Decarbonizing material production not only seems to be the only solution, but it is already underway. This alone may not be enough, as design choices also play an important role, lean, and sustainable design needs to be understood and supported. Design is already evolving from “take, make, use and dispose” to a more reasonable “take, make, use, reuse multiple times and then (eventually) recycle”. When viewed this way, steel is not only the most versatile material but also the most reusable and recyclable, it can be recycled indefinitely without losing its mechanical properties. Efficient design, exploiting a holistic approach, specifying low carbon alternatives (already available today) is the only way to impact less. In this framework, this work gives an overview on the decarbonization journey of the steel industry and on what designers can do to build in a more sustainable way.

1. INTRODUCTION

1. INTRODUCTION

The global construction industry is the world’s largest consumer of raw materials and the built environment accounts for between 25 and 40 percent of total carbon emissions in the world. The sector is also responsible for nearly 40% of raw material use annually and around 39% of the total primary energy use. These shares are expected to grow and consequently the impact of emissions from the production of construction materials will increase [1]. Considering that the world’s building stock is expected to double by 2060, this will add 100-200 gigatons of embodied carbon from construction materials, and it will be the equivalent of building a city as big as New York every 34 days until 2060 [2].

Accounting for, increase in population, the need of new and efficient urbanization, and the fact that almost 75 percent of the infrastructure that will exist in 2050 has yet to be built, the construction industry is only expected to expand, thus providing a significant opportunity to improve its efficiency and transition toward a low-carbon future [2].

Manufacturers and industry in general have engaged to reach net zero carbon within 2050, in line with the European and international strategic objectives. In response to these trends and to the growing demand for green, sustainable, and low-carbon constructions, the construction industry is making efforts to address emissions. Consumers of newly constructed buildings and infrastructure increasingly require the industry to meet standards of energy efficiency, green building rating systems (like LEED and BREEAM), responsible resource management, and resilience. It seems dramatically clear with these forecasts that the journey towards decarbonization of construction material must speed up to meet requirements such as the target of the Paris Agreements. The most promising construction material in terms of low emissions and increasing circularity is steel. Although the steel industry has the stigma of being among the highest-emitting industries (about 7% of global carbon dioxide emissions), the carbon footprint of its manufacturing process has decreased by 37 percent per ton since 1990 [2], and today new low carbon alternatives are cutting emissions faster than before. […]

Leggi l’articolo completo su Costruzioni Metalliche n. 6/2022.