Ing. Francesco Pisciottano

Dipartimento di Ingegneria Civile, Università di Salerno

Ing. Riccardo Zanon

ArcelorMittal Global R&D

Amongst the imperfections causing the deviation between the Eulerian buckling law for a compressed member and the real behavior of an industrial hot-rolled product, residual stresses are one of the main parameters. Studies were carried out from the 1940s, and an extensive European campaign was held in the 1970s. This article reviews the topic with reference to hot-rolled I/H sections, describing the phenomena causing them as well as the different parameters which make an accurate prediction impossible. The most relevant simplified models proposed over the years are recalled, and the most widely adopted measurement techniques are described. A comparison of their effects on the buckling resistance of a compressed column is made through a GMNIA analysis for the case of a high strength steel section, thus also allowing a direct comparison with the analytical curves adopted in the new version of Eurocode 3.

1. INTRODUCTION

1. INTRODUCTION

The stability curves for compressed members currently adopted in the Eurocode are the result of research initiated in the 1940s by the Column Research Council in America and later on by ECCS in Europe.

This research involved extensive experimental campaigns in combination with theoretical and numerical studies [2][3][4][5][6]. The approach is to base the design of compressed member on the theoretical Eulerian buckling theory but applying a reduction factor which takes into account the deviation of the real behavior from the theory. The reduction factor shall be calibrated in function of the section type, steel grade, fabrication standards and in general all parameters which may affect the stability. Thereby it is possible to provide the designer with a relatively simple but consistent way of verification for all available structural sections.

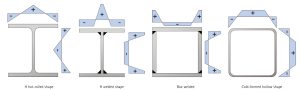

As it is well known, the real column, also called the “industrial” column, differs from the ideal one due to the unavoidable presence of parameters that make the Eulerian elastic-plastic buckling load an upper limit to which the real behavior can approach without reaching it (they are therefore called imperfections). Imperfections are conventionally divided into two categories: geometric imperfections, which consist of the deviation of the actual geometry from the theoretical geometry, and mechanical imperfections, which consist of the deviation of the real behavior of the steel from the ideal elasto-plastic constitutivelaw. Geometric imperfections and mechanical imperfections act simultaneously. […]

Leggi l’articolo completo su Costruzioni Metalliche, n. 4/2025.